Inspiring Technology

CPRI CERTIFIED

MADE IN INDIA

IEC 61439 COMPLIANT

FULL SOLUTION

At ALFA Technologies Pvt Ltd, we manufacture High Quality Sandwich and Air Insulated Bus duct and trunking systems

Products are manufactured compliant to IEC 61439 and are CPRI certified

ABOUT US

ARJ Holding L.L.C is a multinational company that was started in Dubai in 1964. Our core business is in providing products and services in the building sector.

We have four verticals : Water technology, Electro-mechanical Contracting, Real estate development and Private equity investment. We have expanded into new areas that include Landscaping, Construction, and Project management. Our organisation represents some of the world’s biggest firms and our Clients are Governments, Large global players, Leading investment, Industrial and construction companies

We aim to become a foremost Product and Service provider in Electro-mechanical Contracting, Trading in Engineering Products used in the Construction industry and turnkey Landscaping contracts in the GCC / India

We are a firm of highly qualified Engineers, Finance Human resource professionals and business managers. We employee over 2000 people in over 4 countries and play a dominant role in the areas we operate

The Group, through its products and services, touches the lives of tens of thousands of people every day. Be it keeping them in a comfortable environment, or providing the right quality of potable water, sanitation, powering homes and offices through efficient, smart and safe electrical installations, and ensuring life and fire safety through a well engineered fire protection system – we are part of their daily livelihood

This trust of the end user is what keeps us alert and conscious of what we do, how we do and aspires us to offer new and better products and services all the time.

PRODUCTS

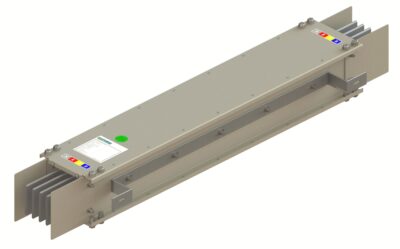

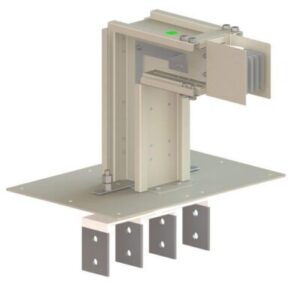

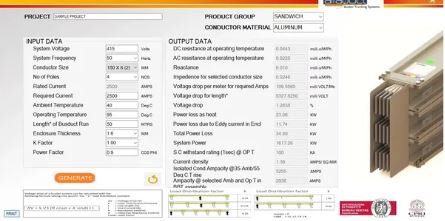

SANDWICH BUS DUCT

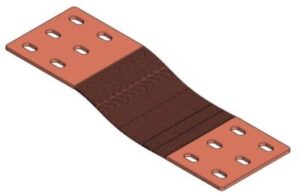

Conductor : Copper or Aluminum

Enclosure : 1.6 mm or 2.0 mm

Current ratings : 400 A to 5000 A

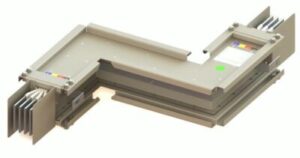

Elements : All types of elements to meet site requirements

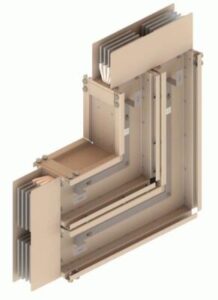

AIR INSULATED BUS DUCT

Conductor : Copper or Aluminum

Enclosure : 1.6 mm or 2.0 mm

Current ratings : 200 A to 2000 A

Elements : All types of elements to meet site requirements

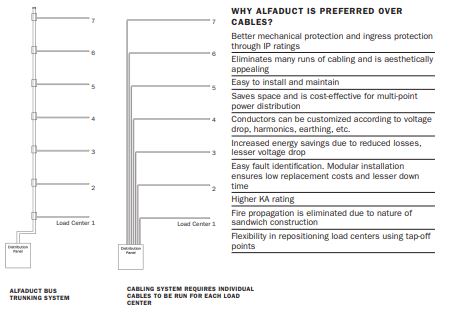

ALFADUCT bus bar trunking systems are utilized in buildings and industrial applications to distribute power to electrical loads

Sandwich and Compact Air insulated bus duct and trunking systems are an ideal and intelligent replacement to conventional power cabling

It offers mechanical protection, is highly flexible, eliminates many runs of cabling, easy to install and maintain, saves lot of space, very presentable in comparison to ugly cabling, conductors can be customized to specific requirement of voltage, harmonics, earthing etc. and saves a lot of cost. There are also electrical savings due to reduced losses, reduced voltage drop and flexibility in repositioning load centers using tap off points

The product is designed to comply to the International Standard of IEC 61439-1 & 6, specification for low voltage and control gear assemblies, a particular requirement for bus duct and trunking systems. Due to its many advantages over conventional cabling, bus bar trunking systems are widely used in Commercial and Residential buildings, Hotels, Factories, IT parks, Data centers, Shopping centers etc

PROJECTS

CLIENT : BOSCH

Product : Sandwich Al Bus duct

Type   : Rising Mains and Bus Duct

Rating   : 400 ~ 4000 Amps

CLIENT : DLF INFOCITY

Product : Sandwich Al Bus duct

Type   : Bus duct and Rising Mains

Rating   : 1000 ~ 3200 Amps

CLIENT : EXPERION

Product : Sandwich Al Bus duct

Type   : Bus Duct

Rating   : 1000 / 1600 /3200 Amps

CLIENT : PURVANKARA

Product : Sandwich Al Bus duct

Type   : Bus Duct

Rating   : 1600 Amps

CLIENT : AMITY SCHOOL

Product : Sandwich Al Bus duct

Type   : Bus Duct

Rating   : 4000 Amps

CLIENT : TAMARAI TECH

Product : Sandwich Al Bus duct

Type   : Bus Duct and Rising Main

Rating   : 2000 Amps

CLIENT : ESI HOSPITAL

Product : Sandwich Al Bus duct

Type   : Bus Duct

Rating   : 5000 Amps

CLIENT : JBM AUTO

Product : Compact Air Insulated Al Bus duct

Type   :Bus Duct and Rising Mains

Rating   : 630 / 800 Amps

BUSINESS APPROACH

We believe that our Sandwich Bus duct and trunking systems cannot be just sold to our Client without ensuring the right application and selection. In order to ensure the end result is achieved by the Client we will be a part of every step in their finalization of the BBT system.

Depending upon the need and type of our client we can:

Evaluate and provide support on the product required, optimal design, technical selection and engineering layout

Install the system with best engineering practices

Test and commission the system

Maintain and carry out service or support on refurbishment when end layouts change

We understand that we won’t get a second chance to make an amazing first impression. Also, we realize that the application of Sandwich bus bar system requires an integrated and coherent acceptance between Consultant, Contractor and Manufacturer. The underlying logic to attain this – SMART Technical staff who have a solid grip on product and application knowledge and who understand the project requirements precisely and come up with an efficient solution

Our trained technical staff will formulate a solution unique to the Project focusing on the following:

• Electrical load requirements

• Nature of Load

• Suitability of Product

• Site Compatibility

• Layout Design

• Cost Factor

• Flexibility

SERVICE

Post installation of the bus duct system, the support team is just a call or email away to resolve any system issues and serve any maintenance and modification requirements Time and time again our alliance with our Clients has only strengthened more post Sales activity. You may make a call or drop a email for any one of the following reasons and our support team will take your case with the highest priority to provide you with the best solution possible at the shortest possible time.

Product Call

Our Sandwich Bus duct and trunking systems goes through stringent quality assurance and stringent installation and pre-commissioning checks. This ensures our product functions satisfactorily for long periods of time without any major maintenance (periodic checks as written in our manual to be practiced).

Any queries in this regard will be welcome from our Client

Service Call

Unforseen events happening, majorly caused by non engineered alterations or failure to carry out periodic maintenance or other unforseen events may required product maintenance.

Our team, at your vicinity, will reach at the earliest to solve the issue and bring the system back to normal operation at the shortest possible time

Modicfication Call

There can be a need to alter or modify the Power Distribution System post installation due to change in the layout at Client’s end.

The Sandwich bus duct and trunking system makes it possible to do any alteration without much wastage of existing routes and operational interference with the minimum downtime.

CONTACT US

Regd Office

New No 25, Old No 16, Rama Street, Nungambakkam, Chennai - 600034

sales@alfaduct.com

+ 91 7904027826

Factory

Survey No 232B, Shivam Estate, Changodhar, Ahmedabad, Gujarat

factory@alfaduct.com

+ 91 7827370124